Driven by their sense of responsibility to their employees, the region of Bavaria, and the environment, Himolla has pursued sustainability measures since 1999. This has led to a number of changes, such as the way they use wood scraps to heat the factory in cold months, or how their new warehouse was constructed with 5,000 square meters of solar panels.

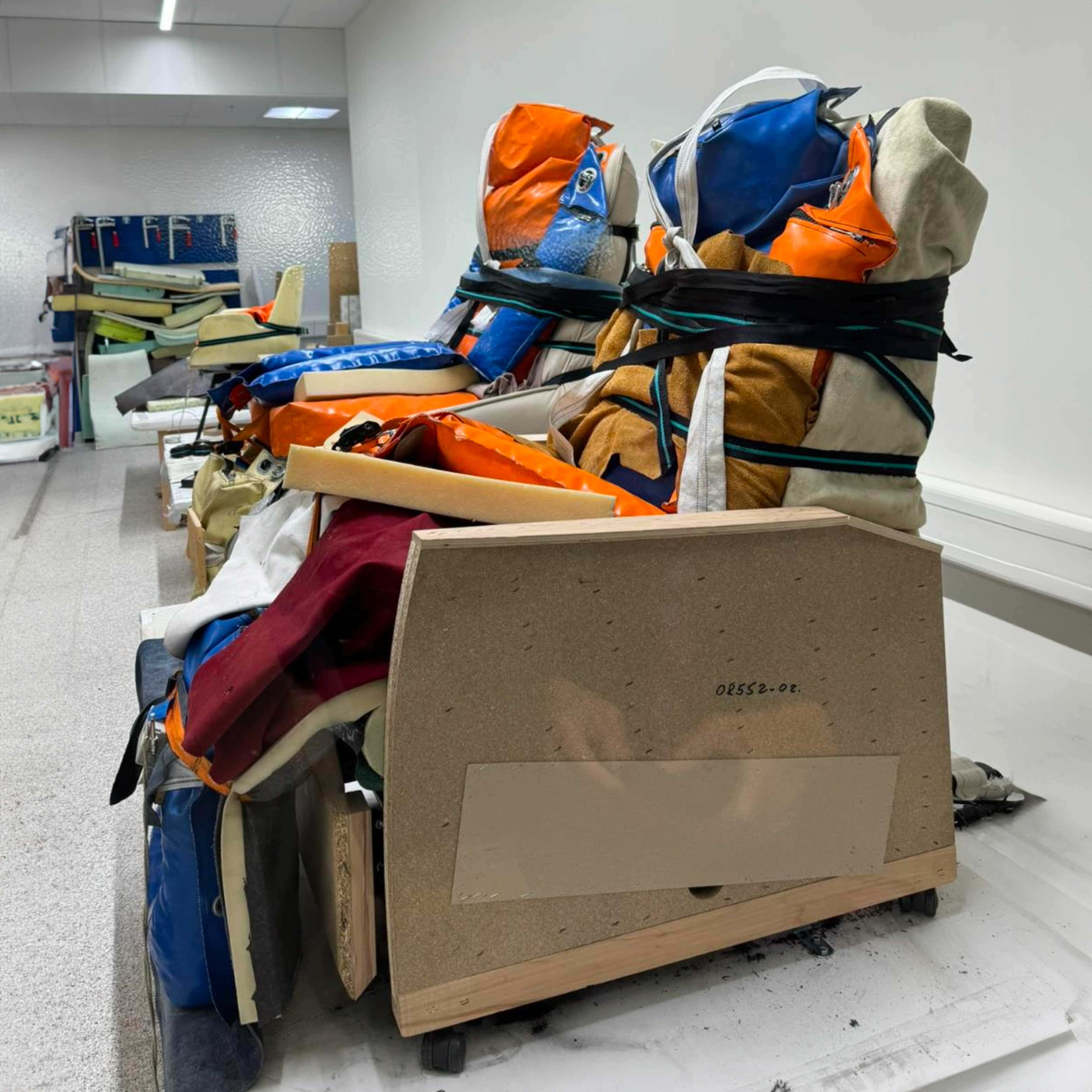

Himolla’s furniture has always been constructed to last: beech wood, the hardest available in Europe, is used for load-bearing frames, while plywood is used in less structurally significant parts of furniture. Support springs are held in place with metal brackets, and plastics are used only when necessary. Foam molds are hand-constructed out of wood, and excess foam is used in packaging.

Speaking of packaging, Himolla ensures that all packaging is recyclable so that there is no waste generated by their products even outside their operations. They have spent time and energy pursuing the laudable goal of zero waste, and they’ve pursued it in all aspects of their work.

Finally, in addition to well-designed and carefully constructed furniture, they carefully test all pieces and all fabrics in specially designed rigs that apply weight and pressure to frames, or temperature and humidity chambers to test upholstery materials. With over 600 fabric and 200 leather options, plus Dacron underlayers, that’s no small project.